SeaSideTech, specialist in embedded electronic solutions design and development for more than ten years, is the ideal partner to support you in your developments.

Technology Readiness Level

SeaSideTech supports you in the realization of your innovation project. Our field of expertise covers TRLs 2 to 8 described in the graph below, and in particular stages 3 to 6 which constitute our core business. As designers/developers, our job is to transform your idea into a qualified industrial product, ready to be deployed on your market, with an optimized time-to-market.

TRL 1

Basic principles observed and reported

Not covered by SeaSideTech, this level of research is generally carried out by official research laboratories

TRL 2

Concepts or applications of the technology formulated

Feasibility study, calculations and system architecture analysis

TRL 3

Analyzed and tested critical function or characteristic proof of concept

Proof of Concept, detailed architecture

TRL 4

Laboratory validation of the component or artefact

Implementation of the results of the previous steps in a first functional prototype (proto A / A+)

TRL 5

Validation in a meaningful environment of the component or artefact

Second prototyping and pre-series phase (Proto B/B+, pre-series)

TRL 6

Demonstration of the system/sub-system model or prototype in a meaningful environment

Pre-series integrated into the client system for system interfacing and qualification

TRL 7

Demonstration of the prototype system in an operational environment

Customer support, on-site debugging, joint testing session (on customer site)

TRL 8

Complete final system qualified through tests and demonstrations

Complete qualification campaign and delivery of associated documentation. Safety case finalized and delivered to client

TRL 9

Final system proven through successful operations/missions

Not covered By Seasidetech, the customer / OEM handles the evidence by operation / transaction

Skills and Tools

Skills and Tools

Skills

Technical Specification

- HW Architecture

- Design for functional safety

- Development in functional safety

- State-of-the-art automotive electronics

- RF design

- Schematic

- Routing

- Testing and qualification (thermal, electrical, EMC…)

- SW Architecture

- State-of-the-art automotive software development

- Firmware scheduler

- Firmware under Linux OS

- Microcontroller application

- SimulLink / Matlab application

- Video processing (ISP, …)

- Video streaming encoding

- Image analysis

- System cybersecurity

- Vehicle communication protocol CAN, FlexRay, LIN

- Communication protocol (Bluetooth, wifi, ethernet…)

- UDS automotive diagnostic protocol

- Tests and validation

- Unit tests

- Electronic and mechanical integration tests

- Mechanical architecture

- Design and development of small-size mechanical parts

Tools / Licences

- Sketchup

- Solidworks

- CADstar

- Matlab Simulink 2015

- Tasking Compiler

- Lauterbach Trace32

- Keil PK166 / MDK

- Parasoft C++ Tests

- Jenkins

- Eagle

- iSystem ActiveProbe

- SEICO testbench *

- VECTOR CANalyzer

- VECTOR CANOe

- Lauterbach CombiProbe / PowerDebug

- Tasking Embeeded Debugger

- minWiggler *

- Salae Logic 16 pro

- Peak PCAN USB Pro FD

- Calibrated KEITHLEY 72A 30V 720W power supply *

- Tektronix MSO2064 Oscilloscope *

- WEISS WKL100 Climate chamber

- REID 500kg ATEX gantry *

Infineon Preferred Design House

(PDH)

![]()

Automotive industry is changing. Fast.

Since the late 1990s, embedded electronics have steadily taken over an increasing number of functions in vehicles, progressively adding key passenger security and comfort features. Driving has shifted from a practical means of getting from one place to another to a full “user experience”. The rise of Electric Vehicles and Autonomous Driving features and solutions reinforces the key role embedded electronics have acquired in the past few years, and this trend seems to be stronger every day.

When starting an embedded electronics development project, selecting the chip that will handle the processing is a key step to reaching a successful outcome and ensuring that your design will deliver the expected functions reliably. Functional Safety considerations add a layer of complexity to the selection of the microcontroller, as they will have significant impact on the global architecture (hardware and software).

Infineon Technologies is a world leader in semiconductor solutions and has developed a wide variety of tools and solutions specifically for automotive applications. The 32-bit AURIX™ TriCore Microcontroller is a powerful family uniting the elements of a RISC processor core, a microcontroller and a DSP in one single MCU. Their architecture ideally suits Functional Safety features thanks to their TriCore architecture allowing a wide range of configurations to meet safety-critical mission profiles. This Range of MCUs fulfill the requirements of the most demanding embedded control applications with performance, real-time behavior, data bandwidth and power consumption performances optimized to meet the needs of a highly demanding industry.

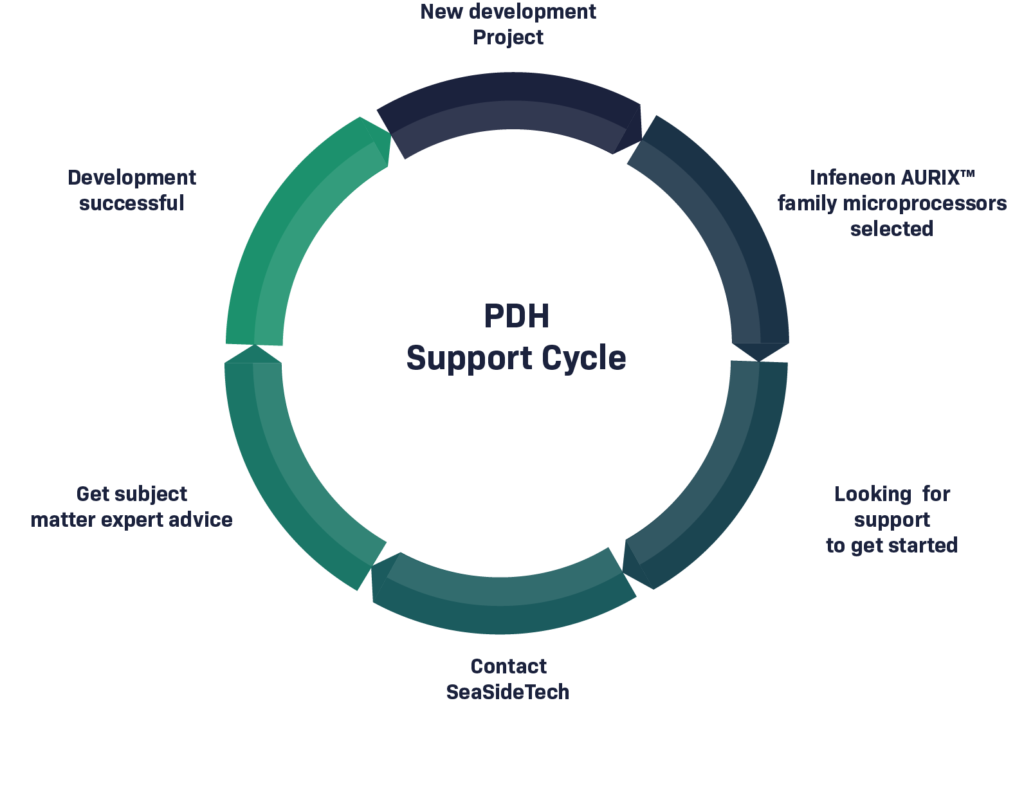

As an expert in Functional Safety Embedded Electronics, SeaSideTech has been using products from the AURIX™ family for years and developed a significant expertise in their deployment in embedded electronics solutions. We are very proud of having been appointed Preferred Design House for this product family, and are always eager to provide advice, support and technical assistance to engineers looking to implement these products in their system. This means you can approach us concerning the challenges you might come across during your AURIX™ project and will be greeted with an enthusiastic support to help make your development project a successful one. Our support comprises engineering services, tools and production services, functional safety expertise and advice, training.

Our range of services articulates as follows

Our range of services articulates as follows

Tools and Middleware for AURIX

SeaSideTech offers the following tools for your AURIX project:

- SafeTpack safety manager

- Security libraries

- MCAL and complex drivers

- Trace and break-out adapters

- Development Tools (compiler, debugger)

- Dynamic and static test tools

AURIX production service

The SeaSideTech production services for your AURIX project comprising:

- Production of prototypes and series products

- Fulfillment (system assembly, logistics, export control)

Engineering Services

Engineering is a SeaSideTech key competence. Design and development services, safety consulting, training and support – no matter what AURIX engineering problem you might have, our AURIX experts will help drive you to success:

- Software development (low level driver, complex device driver, applications)

- Unit tests

- Hardware development (PCB design)

- Development documentation according to safety standards

- System concept and design (hardware, software)

- Functional safety

- Safety standards (IEC 61508, ISO 26262, …)

- Safety concept

- Certification requirements

- Process consulting (according to standards)

PDH

PDH

Support Cycle